The construction of the welding hall's heat collection line did not interrupt production, but if necessary the work was carried out in the evening and weekend shifts.

Large-scale renewal projects at TK-Vilmet

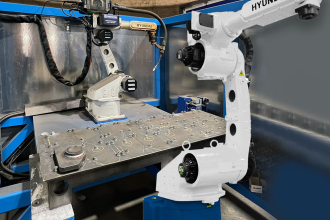

TK-Vilmet has large-scale, ongoing investment projects in order to increase production capacity and enhance energy management. Recent acquisitions, such as the modern Tos Varnsdorf machine tools and the Hyundai HA006B welding robot station with Kemppi A7 welding equipment are part of the company's continuous development work. By modernising the machine fleet, the company strengthens the reliability and quality of the demanding medium-weight subcontracting machinery.

TK-Vilmet invests in heat recovery system

The company also invests in its production environment by renewing the air conditioning and heating system of the welding hall. The abandonment of oil heating is an important step in the sustainable recovery of the economy and in the response to the climate crisis and natural degradation.

Within a few months, new ventilation units and a collection line were installed in the welding hall. In heat recovery of ventilation, the heat energy of the exhaust air is transferred back to the supply air and to the heating system of the property. The new system achieves significant savings in heating expenses and improves the energy efficiency of the welding hall. Good air quality and a steady temperature also have a direct impact on employee comfort and occupational safety.

» Read more about the project at www.lekogroup.fi/news